Forklift Pockets – Construction, Standards, Safe Use

Forklift Pockets (also called pockets for forklift trucks, handling openings) are integrated as rectangular openings in the longitudinal beams of the lower frame of certain types of shipping containers. Their primary purpose is to enable safe, quick and efficient handling of the container using special forklift trucks (FLTs), especially in environments where crane use is not possible or practical. These pockets are a fundamental structural element for ground logistics, loading, unloading and overall handling of containers in depots, warehouses, construction sites or during customer deliveries.

Detailed Technical Review: Construction, Standards, Safe Use

This article provides a comprehensive overview of the construction, standards and safe use of forklift pockets on shipping containers. It is based on the latest technical information and industry standards (especially ISO 1496‑1).

What Exactly Are Forklift Pockets?

- Function and Location:

Forklift pockets are not merely “holes in the frame,” but precisely designed tunnels that pass through the lower side beams of the container. They are positioned parallel to the longitudinal axis of the container (most often in the middle of a 20‑foot container) and allow the forklift forks to be inserted through the entire container. - Significance:

Their presence fundamentally changes handling possibilities, especially for empty or lightly loaded containers. They enable rapid maneuvering in yards, warehouses, construction sites and during delivery to the customer. - Typical Use:

Most common on 20‑foot containers; rarely on smaller or special‑type containers. On 40‑foot containers forklift pockets are an exception due to safety concerns.

Purpose and Key Benefits of Forklift Pockets

| Advantage | Description |

|---|---|

| Flexibility | Quick relocation without waiting for a crane, saving time during loading/unloading and container yard organization. |

| Handling in Confined Spaces | Forklifts are more maneuverable than cranes, allowing movement in narrow aisles and tight spaces. |

| Reduced Operating Costs | Operating a forklift is cheaper than a crane; an economical solution for companies frequently handling empty or lightly loaded containers. |

| Simplified Logistics | Forklift handling simplifies the entire logistics chain from unloading to final container placement. |

Construction, Standards and Technical Specifications

Materials and Reinforcement

- Material:

The pockets are an integral part of the frame made of high‑strength steel (usually CORTEN), which ensures long service life even under harsh conditions. - Reinforcement:

The area around the openings is reinforced by welding additional steel plates and gussets, especially on the upper surface of the beam. This reinforcement prevents weakening of the structure and ensures the container can withstand bending and shear forces during handling.

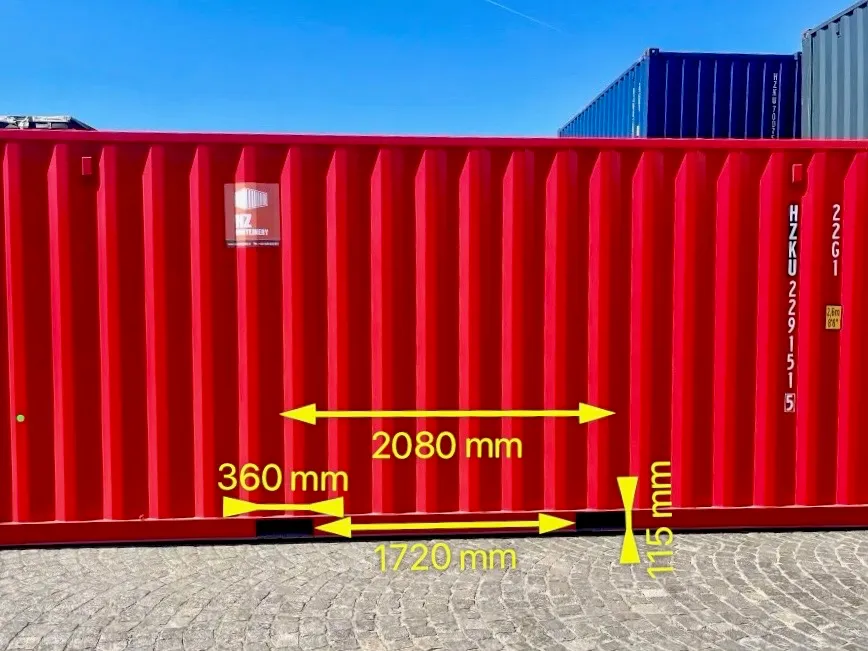

Dimensions and Placement

| Parameter | Typical Value | Notes |

|---|---|---|

| Pocket opening | approx. 355 mm (width) × 115–150 mm (height) | Standard dimensions according to ISO and manufacturers. |

| Pocket spacing | approx. 2050 mm (center‑to‑center) | Provides optimal stability when lifting. |

| Pocket length | Extends across the full width of the container | Forks must pass through and protrude slightly. |

| Ceiling construction | Always closed (solid) | Prevents fork slip‑out and increases safety. |

| Pocket bottom | Solid / with drainage holes | Holes allow water drainage and cleaning. |

- Standards:

Basic technical requirements for pockets are derived from ISO 1496‑1 (general‑purpose containers). The standard specifies not only dimensions but also the minimum required frame strength at the pocket location. For offshore containers the minimum opening size is 200 × 90 mm.

Practical Dimension Examples

- 20′ container: typically two pockets spaced about 2050 mm apart, pocket size approx. 355 × 115–150 mm.

- Specialized containers: dimensions can be adjusted according to purpose and customer requirements.

Which Containers Have Forklift Pockets?

| Container Type | Forklift Pockets Presence | Reason |

|---|---|---|

| 20′ (6 m) containers | Yes (overwhelming majority) | Ideal weight and dimensions for forklifts. |

| 40′ (12 m) containers | Usually no | High weight, risk of bending, loss of stability. |

| Smaller / specialized containers | Depends on type, often on request | Can be added as a custom option, especially for storage units. |

| Reefer / refrigerated containers | Individual basis | Depends on construction and manufacturer. |

Note: Handling 40′ containers with a forklift is very dangerous due to frame bending and instability. These containers are primarily designed for crane lifting (attachment to corner castings).

Additional Handling Features on the Container

- Corner castings: Standardized steel blocks on all corners, intended for crane attachment, stacking and securing during transport.

- Gooseneck tunnel: Cutout in the floor (on 40′ containers) allowing secure placement on a special gooseneck trailer, reducing train height and improving transport stability.

- Grappler pockets: Openings for grappler claws that enable side lifting of the container, often used in space‑constrained sites.

Safe Use and Handling – Forklift Safety

Forklift (FLT) Requirements

| Criterion | Recommendation / Minimum Value | Risk if Not Met |

|---|---|---|

| Load capacity | Minimum 5 t (empty 20′), ideally 7 t+ | Undersized forklift → risk of overturning, damage. |

| Fork spread | Minimum 2050 mm (matching pocket) | Smaller spread → instability, overturning. |

| Fork length | Minimum 2.4 m (8 ft), across full container width | Short forks → uneven loading, floor damage. |

| Drive type | Robust diesel/LPG forklift for outdoor use | Warehouse‑only forklifts are unsuitable. |

Safe Handling Procedure

- Inspect pockets before handling: Ensure they are free of debris (dirt, ice, stones, tools). Obstructions can cause instability.

- Know the weight: Always verify the container’s weight (including cargo). Never exceed the forklift’s load capacity.

- Flat, firm surface: Operate only on a solid, level surface. Slopes or soft ground are extremely hazardous.

- Correct fork insertion: Approach perpendicularly, insert forks fully to the stop, lift smoothly and monitor stability.

- Transport: Keep the container low to the ground and slightly tilted backward to increase stability.

- Operator training: Only trained and certified personnel may perform the operation.

Common Issues and Prevention

- Pocket blockage: Perform regular inspections; consider installing pocket covers.

- Corrosion: Routine maintenance and repainting greatly extend container life.

- Use of inappropriate equipment: The most frequent cause of accidents – always use forklifts with adequate capacity.

Overview of ISO 1496‑1

- ISO 1496‑1: International standard for dimensions and construction of general‑purpose containers. It sets minimum requirements for strength, handling‑opening dimensions and overall structural integrity, including strength at the forklift pocket locations.

- Key requirements:

- Minimum opening size

- Frame reinforcement at pocket locations

- Resistance to repeated lifting and handling

Practical Tips for Owners and Operators

- When purchasing a container, always confirm that it has the required pockets (especially for 20′ containers).

- If you will handle the container frequently with a forklift, invest in a high‑quality industrial forklift and provide proper training for operators.

- Regularly inspect the condition of pockets and the frame, particularly if the container is exposed to outdoor elements.

- For specialized containers (offices, residential, storage) pockets can often be added as a custom option.

Other container news...

What does ONE TRIP shipping container mean?

Welcome to our detailed article, where you will find the most detailed explanation of the term ONE TRIP shipping container – technical parameters, standards, life cycle, advantages, disadvantages and practical advice for purchasing.

What colors of shipping containers are the most used and most in demand?

The choice of shipping container color is a strategic issue of safety, durability, operational efficiency and corporate identity. The most popular shades (anthracite gray, gentian blue, light gray, pure white) are the result of long-term practice and reflect the requirements for durability, versatility and visual appeal. Modern coating systems meet strict standards (ISO, CSC) and, thanks to advanced pigments, offer better thermoregulation. When choosing, we recommend taking into account not only aesthetics, but also practical aspects – the type of cargo, environment, maintenance requirements and future use of the container.

Terminal Handling Charges (THC) in European and Czech Ports

Terminal charges (THC) are a complex and variable cost component in international transport. For Czech exporters and importers, understanding the structure, development and method of charging these charges is key to effective logistics cost management. Transparent communication with carriers and forwarders, the right choice of port and Incoterms and an emphasis on technological innovations in ports can fundamentally help optimize overall transport costs.

Salt Air and Shipping Containers

Salt air is a relentless and often underestimated enemy of steel shipping containers. Knowing how it works is key, but above all, a systematic approach to prevention, maintenance and repair is key. By following the recommended procedures, you can significantly extend the life of your container and protect your investment and the goods you are transporting.