SHIPPING CONTAINER 40 HC

The shipping container 40 HC is another frequently requested container after classic storage containers. Especially for its higher height and greater length. This type of container is often used for storing bulky goods outside of shipping. These can be large bulky machines, cars or pallet goods.

Compared to the classic storage container 20, you can place roughly twice as many goods in this container without dividing the goods into 2 separate units. However, assuming the same load capacity, which is the same for a hc 40 shipping container as for a 20 hc.

It is used especially in cases where the HC 20 shipping container is not enough for you and you need to place several pallets not only on top of each other, but also in height, for example. If you are using the container, for example, for further reconstruction and you are planning larger spaces, you can make 2 rooms out of the HC 40 container. What is important is that an internal clearance of 2.5m may be required for a building permit. Which meets only the HC (High Cube) container, not a classic storage container.

| STORAGE CONTAINER HIGH CUBE – HC higher BUY | ||||||||||

| External dimensions (m) | Internal dimensions (m) | Dimensions doors (m) | Weight kg | Capacity | |||||||

| CONTAINER TYPE | length | wide | height | length | wide | height | wide | height | container | maximum load capacity | m3 |

| 40′ HC | 12,192 | 2,438 | 2,896 | 12,032 | 2,352 | 2,698 | 2,34 | 2,585 | 3750 | 28250 | 76,4 |

| 40′ HC Isolated | 12,192 | 2,438 | 2,896 | 11,582 | 2,292 | 2,577 | 2,34 | 2,585 | 3750 | 28250 | 76,4 |

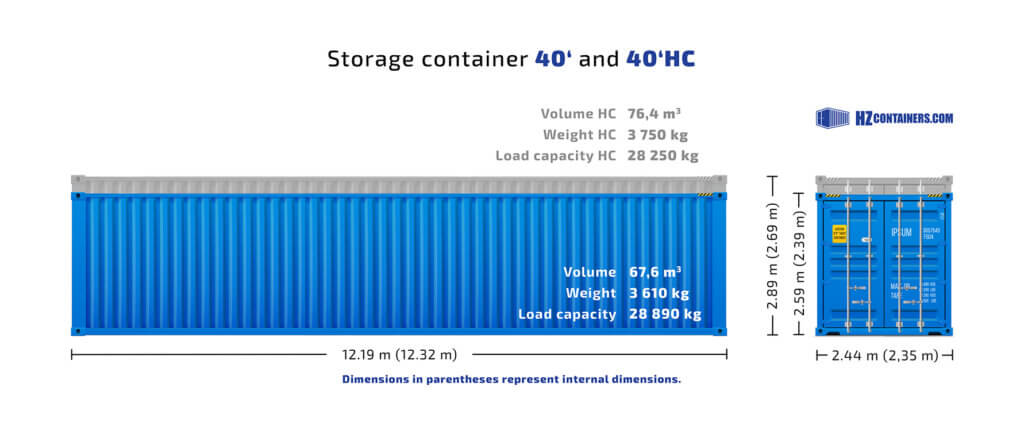

The external dimensions of the shipping container 40 HC are: length 12.192m / width 2.438m and height 2.896m. With a permissible deviation of +-5 to 6mm

Internal dimensions: length 12.032m / width 2.352m / height 2.698m again with a possible deviation of +- 5 to 6mm

Door dimensions: width 2.393m / height 2.585m with a possible deviation of +-5mm

The maximum load for a 40 HC shipping container is: 76.4m3 / the maximum permissible weight including the container is 30,480 kg with a 2% overload tolerance

SPECIFICATION FOR SHIPPING CONTAINER 40 HC

Although the container is twice as large as the 20 HC shipping container, the same technological procedures and strength of materials are used for production. For this very reason, the container is twice as bulky, but the maximum load of the container is the same as for a 20 hc container. So it always depends on what you need to store in the container and what is the required load weight for you.

There are always 2 ventilation grids in the container as standard. Each is attached to the top right of each sidewall with three 5.0mm diameter aluminum hinged screws. In addition, they are sealed with sealant to prevent leakage.

All steel surfaces including welds are blast blasted prior to coating to remove any contaminants from the container. So that the coating and overall resistance of the container to external influences is not disturbed in the future. They are painted with an epoxy primer. After the primer has dried, the outside of the container is painted again with a second layer of epoxy paint. And finally, a top paint with high strength, e.g. RAL 7016. The inner side of the container is provided with a high strength coating based on epoxy resin hardened with polyamide. The dry film thickness of the topcoat is 40 microns for exterior and interior.

PRODUCTION OF CONTAINER

The HC shipping container is made from anti-corrosion steel: Corten A from vertical corrugated steel sheets – the so-called trapezoidal sheet. The wooden floor is made of 28 mm thick hardwood plywood. After its completion, all substructures and the floor are provided with an asphalt coating. The thickness of the dry film is at least 200 microns.

During the production of each container, requirements are set to withstand temperatures from -30°C to +80°C without affecting the structure or water resistance of the container. The door is manufactured from 3.00 mm horizontal pressed corrugated steel sheets for the top and bottom. Middle side of the door is 2.0 mm thick. Container has two double doors on the rear frame and each can rotate approximately 270 degrees. The side walls of the container are made of steel panels with a thickness of 1.6 mm.

All door hardware is hot-dip galvanized to a thickness of approximately 75 microns. Connecting material such as screws, nuts, threads, as well as hinges, cam handles and fixing fittings are galvanized.