CORNER CASTING

Corner castings, also known as corner blocks for shipping containers, are a key component in the world of shipping containers. These structural elements are essential for the functionality and stability of ISO shipping containers. This glossary entry aims to provide a comprehensive understanding of what corner castings are, their significance, material composition, standard specifications, and their role in the logistics and transportation industry.

What are corner castings – blocks?

Corner castings – blocks are robust, three-hole steel blocks placed in each corner of an ISO shipping container. They serve as the main structural elements that allow containers to be securely attached to various modes of transportation — whether by ship, train, or truck. Additionally, they facilitate container stacking, ensuring stability during transportation. Corner castings, or corner blocks, are essential for lifting and securing containers, ensuring they can be safely transported between different modes of transport.

Material Composition

Corner blocks for shipping containers are typically made of cast iron, a material chosen for its strength, durability, and ability to withstand heavy loads and harsh environmental conditions. Cast iron is preferred for its:

- Strength and durability: Essential for bearing the weight and pressure of stacked containers.

- Weldability: Allows secure attachment to other structures or containers.

- Heat resistance: Suitable for various environmental conditions without degradation.

Some corner castings are also made from aluminum or stainless steel, depending on specific needs such as weight reduction or increased resistance to corrosion.

ISO 1161 Standard

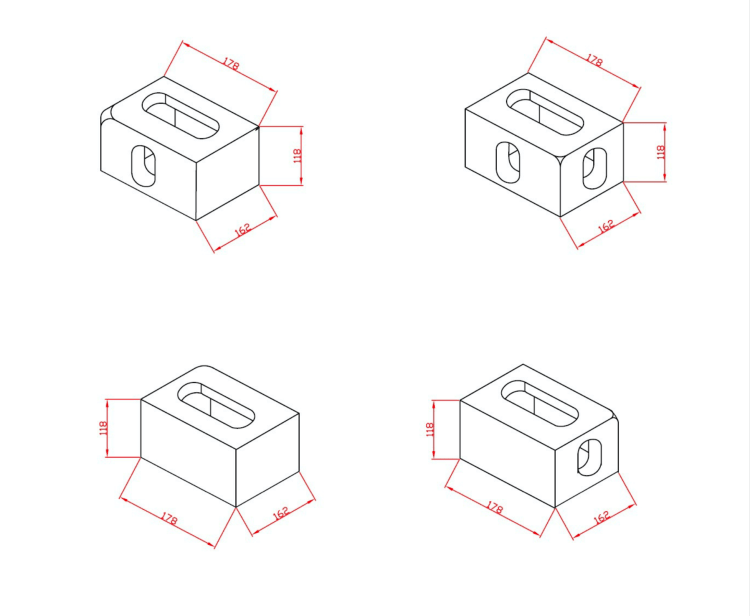

The International Organization for Standardization (ISO) has established ISO 1161 as the standard governing the dimensions, strength, and functional requirements for container corner castings. This ensures global compatibility and safety, as all ISO-certified containers must adhere to these specifications. The standard dimensions for corner castings are typically 178 mm x 162 mm x 118 mm, with precise tolerances to fit lifting devices and intermodal systems. These specifications are crucial for ensuring universal compatibility of corner castings in the global shipping industry.

Types of corner castings (corner blocks for shipping containers)

Each ISO container uses eight corner castings, divided into four types based on their location:

- Upper left (TL)

- Upper right (TR)

- Lower left (BL)

- Lower right (BR)

These corner castings are mirror images of each other, with significant differences between the upper and lower castings. Upper castings have holes on the long side and a stacking hole on top, while lower castings have a stacking hole on the bottom.

Functionality and Use

Corner castings are an integral part of the efficiency and safety of shipping containers. Their functions include:

- Lifting and Handling: Designed to withstand forces during lifting by cranes and forklifts.

- Intermodal Connection: Allow safe connection and stacking, enabling easy transfer of containers between different modes of transport.

- Stability: Provide a stable base when containers are stacked on top of each other on ships or in storage yards.

Corner castings are crucial for maintaining the integrity and safety of containers during transport, preventing losses and damage.

Installation and Maintenance

Installation of corner castings typically involves welding, ensuring a secure and durable connection to the container. Maintenance mainly involves regular inspections for signs of wear or corrosion, especially in harsh environmental conditions, to maintain structural integrity.

Certification and Quality Control

To ensure high standards of safety and reliability, corner castings undergo thorough testing and must be certified according to ISO 1161. This includes testing for mechanical strength, environmental resistance, and compliance with dimensional specifications. Certification from entities such as GL, BV, CCS, ABS, and others may be required depending on regional regulations and specific applications.

Market and Availability

Corner castings for shipping containers are widely available from manufacturers specializing in industrial castings and container components. Leading suppliers often offer corner castings with various certifications and customized specifications to meet the diverse needs of the industry.

HZ CONTAINERS s.r.o. typically has these corner castings in stock. Quantity available upon request.

Corner castings for shipping containers, also known as “corner blocks,” are indispensable for the global shipping industry, ensuring safe and efficient transport of goods across continents. Their standardized design, robust material composition, and key role in container logistics emphasize their importance. Understanding these components is essential for professionals involved in transportation, logistics, and container manufacturing, as well as for those interested in the structural engineering of transport systems.